Aikace-aikace: Yadu amfani a brushless motor, m magnet masana'antu motor, yadi motor, mota motor, m magnet kai tsaye drive motor, mikakke motor, kwandishan injin, inji kayan aiki dindindin maganadisu motor, Marine janareta, m maganadisu janareta, m maganadisu propulsion motor , hakar ma'adinai dindindin maganadisu, hada biyu motor, sinadaran dindindin maganadisu motor, drive motor for EV, famfo motor, EPS motor, firikwensin da sauran yankin.

Samfurin da aka keɓance: maganadisu duk an tsara su, tsawon na iya zama daga 0.5mm-200mm, nisa daga 0.5mm-150mm, kauri daga 0.5mm-70mm, wanda zai iya saduwa da buƙatun abokan ciniki.

Rufi: NdfeB maganadisu yana da sauƙin oxidize, don haka kullum yana buƙatar sutura, murfin da aka saba amfani dashi a kasuwa kamar:

1. ZN plating (nau'in karfe shafi, gishiri fesa gwajin iya isa 24-48 hours, high kudin yi, don haka yana daya daga cikin mafi kyau zabi ga mafi yawan abokan ciniki).

2. NICUNI (wani nau'in shafi na karfe, gwajin gwajin gishiri na iya isa 48-72 hours, aikin farashi ya fi girma fiye da ZN, amma har yanzu ana amfani da shi sosai a kasuwa yanayin taron yana da tsanani, samfurin lalata juriya da bukatun abokin ciniki zai iya. zabi).

3. Epoxy (rufin da ba na ƙarfe ba, rashin ƙarfin maganadisu, na iya rage asarar eddy na yanzu, gwajin gwajin gishiri zai iya kaiwa awanni 72-96, farashi mafi girma fiye da ZN wani shafi na NICUNI.)

4. Sauran shafi da kuma amfani da: Phosphate, Sn, Au, Ag, Parylene da sauransu ...

Haƙuri: Yawanci haƙurin mu na maganadisu shine +/- 0.05mm bayan shafi.

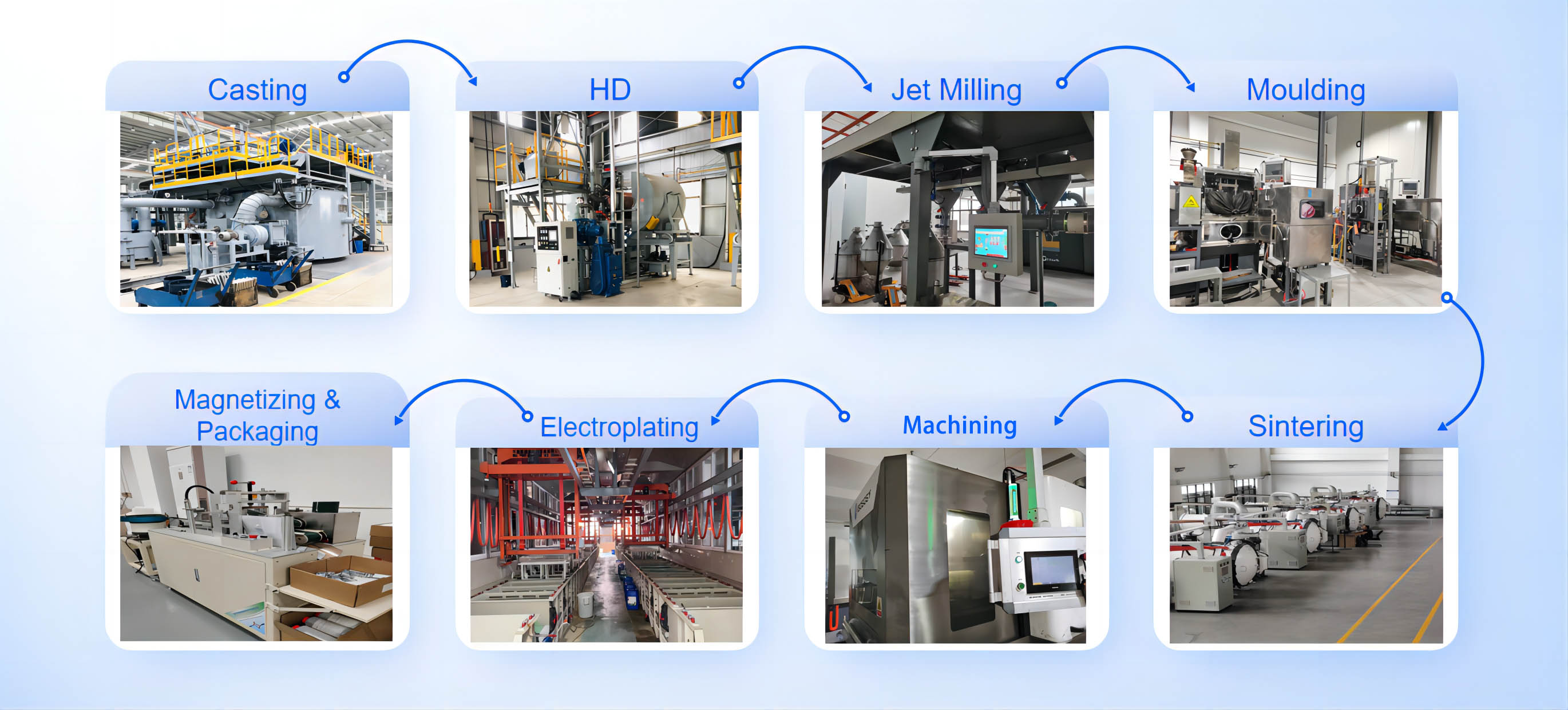

Tsarin Samar da NdFeB

Gabatarwa mai rufi

| Surface | Tufafi | Kauri μm | Launi | Sa'o'i SST | Awanni PCT | |

| Nickel | Ni | 10 zuwa 20 | Azurfa mai haske | >24;72 | >24;72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10 zuwa 20 | Baƙar fata mai haske | >48;96 | >48 | |

| Cr3+ Zinc | Zn C-Zn | 5 zuwa 8 | Brighe Blue Launi mai sheki | > 16 zuwa 48 > 36 ~ 72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 zuwa 25 | Azurfa | > 36 ~ 72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10 zuwa 15 | Zinariya | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 zuwa 15 | Azurfa | >12 | >48 | |

| Epoxy | Epoxy | 10 zuwa 20 | Black/Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15 zuwa 30 | > 72 ~ 108 | --- | |||

| Zn+Epoxy | 15 zuwa 25 | > 72 ~ 108 | --- | |||

| Abin sha'awa | --- | 1 ~3 | Dark Grey | Kariya na wucin gadi | --- | |

| Phosphate | --- | 1 ~3 | Dark Grey | Kariya na wucin gadi) | --- | |

Halayen Jiki

| Abu | Ma'auni | Ƙimar Magana | Naúrar |

| Magnetic Auxiliary Kayayyaki | Matsakaicin Yanayin Zazzabi Na Br | -0.08-0.12 | %/ ℃ |

| Matsakaicin Yanayin Zazzabi Na Hcj | -0.42-0.70 | %/ ℃ | |

| Takamaiman Zafi | 0.502 | KJ·(Kg ·℃)-1 | |

| Curie Zazzabi | 310-380 | ℃ | |

| Injiniyan Jiki Kayayyaki | Yawan yawa | 7.5 ~ 7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Juriya na Lantarki | 1.4x10-6 | μQ · m | |

| Ƙarfin Ƙarfi | 1050 | MPa | |

| Ƙarfin Ƙarfin Ƙarfi | 80 | Mpa | |

| Lankwasawa Ƙarfin | 290 | Mpa | |

| Thermal Conductivity | 6 zuwa 8.95 | W/m · K | |

| Modul na Matasa | 160 | GPA | |

| Thermal Fadada (C⊥) | -1.5 | 10-6 / ℃-1 | |

| Fadada thermal (CII) | 6.5 | 10-6 / ℃-1 |

Nunin Hoto