Bayan haka, maganadisu na SmCo suna da wasu fasalulluka:

Dogaran aiki: SmCo maganadiso ne musamman juriya ga demagnetization sa su abin dogara a da yawa wurare.

Lalacewa da juriya na iskar shaka: Saboda ƙarancin ƙarfe a cikin kayan haɗin gwiwar, SmCo maganadiso yana da kyakkyawan juriya na lalata.Ba kamar NdFeB ba, SmCo maganadiso baya buƙatar electroplating.

Zazzabi kwanciyar hankali: SmCo iya ci gaba da Magnetic ƙarfi a high yanayin zafi (249-300 ℃) da sosai low yanayin zafi (-232 ℃).

Gaggawa kayan: Lokacin a sintering, kayan na iya zama m, saboda yana da gaggautsa da sauki crack , da sarrafa yana da iyaka, wanda na gargajiya sarrafa hanyoyin ba su iya aiki.Duk da haka, yana iya zama ƙasa, amma kawai idan an yi amfani da yawan adadin coolant.Wannan saboda mai sanyaya na iya rage haɗarin wuta daga fashewar zafi da ƙurar niƙa mai oxidized.

Aikace-aikace:

1. Manyan motocin PM.Motocin PM gabaɗaya yawanci suna amfani da maganadisu na ferrite ko maganadiso NdFeB.Amma a wuraren da zafin jiki ya zarce 200 ℃ ko kuma turkey ɗin yana da girma, kawai Motocin SmCo PM ne kawai suka cancanta.

2. Electroacoustic na'urorin a cikin high-karshen lasifika tsarin.

3. Tsarin kayan aiki abin dogara sosai.Yawancin kayan aikin da ake amfani da su a sararin samaniya, jirgin sama, likita da sauran filayen dole ne su yi amfani da maganadisu na dindindin na SmCo don tabbatar da babban aminci da cikakken aminci.

4. A cikin tsarin radar mai mahimmanci da tsarin sadarwa, ana amfani da babban adadin bututun raƙuman tafiya, magnetrons, tubes masu bi, bi da bututun raƙuman ruwa, gyrotrons da sauran na'urori masu amfani da wutar lantarki, kuma magneto na SmCo suna yin katako na lantarki tare da motsi tare da hanyar da aka tsara.

5. SmCo Magnetic extractors a cikin zurfin rijiyoyin kasa 3000 mita, da kuma SmCo Magnetic drive (famfo) a high zafin jiki yanayi na 200 ℃.

6. Magnetic tsotsa shugaban, Magnetic SEPARATOR, Magnetic hali, NMR, da dai sauransu.

Jerin Grade na SmCo Magnet

| Kayan abu | No | Br | Hcb | Hcj | (BH) max | TC | TW | (Br) | Hcj | ||||

| T | |KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | ℃ | % ℃ | % ℃ | ||

| 1:5 SmCo5 (Smpr) Co5 | YX-16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.050 | -0.30 |

| YX-18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-88 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.050 | -0.30 | |

| YX-20 | 0.90-0.d4 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.050 | -0.30 | |

| YX-22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-94 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.050 | -0.30 | |

| YX-24 | 0.96-1.00 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.050 | -0.30 | |

| 1:5 SmCo5 | YX-16S | 0.79-0.84 | 7.9-8.4 | 612-660 | 7.7-83 | ≥ 1830 | ≥ 23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| YX-18S | 0.84-0.89 | 8.4-89 | 644-692 | 8.1-8.7 | ≥ 1830 | ≥ 23 | 135-151 | 17-19 | 750 | 250 | -0.040 | -0.28 | |

| YX-20S | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-92 | ≥ 1830 | ≥ 23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 | |

| YX-22S | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-95 | ≥ 1830 | ≥ 23 | 167-183 | 21-23 | 750 | 250 | -0.045 | -0.28 | |

| YX-24S | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥ 1830 | ≥ 23 | 183-199 | 23-25 | 750 | 250 | -0.045 | -0.28 | |

| 1: 5 (SmGd) Co5 | LTc(YX-10) | 0.62-0.66 | 62-6.6 | 485-517 | 6.1-6.5 | ≥ 1830 | ≥ 23 | 75-8A | 9.5-11 | 750 | 300 | 20-100 ℃ +0.0156% ℃ 100-200 ℃ +0.0087% ℃ 200-300 ℃ +0.0007% ℃ | |

| Ce (CoFeCu) 5 | YX-12 | 0.7Q-0.74 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

| Sm2 (CoFeCuZr)17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥ 1990 | ≥ 25 | 175-191 | 22-24 | 800 | 350 | -0.025 | -0.20 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1990 | ≥ 25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1990 | ≥ 25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1990 | ≥ 25 | 220-240 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

| YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1990 | ≥ 25 | 230-255 | 29-32 | 800 | 350 | -0.035 | -0.20 | |

| YXG-22 | 0.93-0.97 | 9.3-97 | 676-740 | 8.5-93 | ≥ 1453 | ≥ 18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 87-9.6 | ≥ 1433 | ≥ 18 | 175-191 | 22-24 | 800 | 300 | -0.025 | -0.20 | |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1433 | ≥ 18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1433 | ≥ 18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1453 | ≥ 18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1433 | ≥ 18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0.025 | -0.20 | |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

| YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

| (SmER) 2 (CoTM) 17 | LTC (YXG-22) | 0.94-0,98 | 9.4-9.8 | 668-716 | 8.4-9.0 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -50-25 ℃ +0.005% ℃ 20-100 ℃ -0.008% ℃ 100-200 ℃ -0.008% ℃ 200-300 ℃ -0.011% ℃ | |

| Kaddarorin jiki na Samarium Cobalt | ||

| Siga | SmCo 1:5 | SmCo 2:17 |

| Curie zafin jiki (℃) | 750 | 800 |

| Matsakaicin zafin aiki (℃ | 250 | 300 |

| Hv (MPa) | 450-500 | 550-600 |

| Girma (g/cm³) | 8.3 | 8.4 |

| Yawan zafin jiki na Br (%/℃) | -0.05 | -0.035 |

| Yawan zafin jiki na iHc (%/℃) | -0.3 | -0.2 |

| Ƙarfin ɗaure (N/mm) | 400 | 350 |

| Ƙarfin karya mai juyawa (N/mm) | 150-180 | 130-150 |

Aikace-aikace

SmCo maganadisu ana amfani da ko'ina a cikin sararin samaniya, babban zafin jiki resistant mota, microwave kayan aiki, sadarwa, likita kayan aiki, kida da kuma mita, daban-daban Magnetic watsa kayan aiki, na'urori masu auna sigina, Magnetic sarrafawa, murya nada Motors da sauransu.

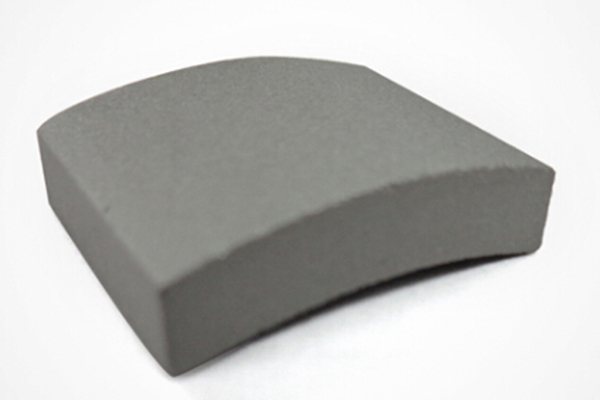

Nunin Hoto

-

Neman Zagaye NdFeb a cikin Electroacoustic

-

Bincika Bambance-bambancen Girman Magnets na Ferrite masu alaƙa

-

Yanki NdFeB Magnet don Motocin Lantarki: Manyan ...

-

Farashin masana'anta Na Rabin Ring NdFeB Karfin Magnet...

-

Dillalan Dillalan Kyautar Samfurin N52 Block Neod...

-

Babban Zaɓi don Ƙarfin Neodymium Magnet...