Alnico dindindin maganadisu kayan ba za a iya tsara a matsayin tsarin sassa saboda fasali na low inji ƙarfi, high taurin, brittleness, kuma matalauta machinability.Ana iya amfani da ɗan ƙaramin niƙa ko EDM yayin aiki, wasu hanyoyin kamar ƙirƙira da sauran mashin ɗin ba za a iya amfani da su ba.

AlNiCo ana samar da shi ne ta hanyar simintin gyare-gyare.Bugu da kari, foda karfe kuma za a iya amfani da su yi sintered maganadiso, wanda yana da dan kadan m aiki.Za'a iya sarrafa Cast AlNiCo zuwa girma dabam da siffa daban-daban yayin da samfuran AlNiCo da aka ƙera galibi suna kanana.Kuma kayan aikin sintered AlNiCo suna da mafi kyawun jure juzu'i, abubuwan maganadisu sun ɗan yi ƙasa kaɗan amma injin ya fi kyau.

Amfanin AlNiCo maganadiso shine babban remanence (har zuwa 1.35T), amma ƙarancin shine ƙarfin tilastawa yayi ƙasa da ƙasa (yawanci ƙasa da 160kA/m), kuma madaidaicin demagnetization ba layi bane, don haka AlNiCo shine maganadisu mai sauƙi zama magnetized kuma mai sauƙin ragewa.Lokacin zayyana da'irar maganadisu da kera na'ura, ya kamata a biya kulawa ta musamman kuma magnet ɗin dole ne a daidaita shi a gaba.Don gujewa ɓarnawar ɓarna ko karkatar da rarrabuwar ma'aunin maganadisu, an haramta shi sosai a tuntuɓar kowane nau'in ferromagnetic yayin amfani.

Cast AlNiCo na dindindin maganadisu yana da mafi ƙarancin jujjuya yanayin zafin jiki a tsakanin kayan maganadisu na dindindin, zafin aiki zai iya kaiwa zuwa 525°C, da zafin jiki na Curie zuwa 860°C, wanda shine madaidaicin abu na maganadisu tare da madaidaicin Curie.Saboda kyakkyawan kwanciyar hankali da kwanciyar hankali, AlNiCo maganadiso ana amfani da su sosai a cikin injina, kayan kida, na'urorin lantarki, da injin maganadisu, da sauransu.

Jerin Grade na AlNiCo Magnet

| Daraja) | Ba'amurke Daidaitawa | Br | Hcb | BH max | Yawan yawa | Madaidaicin zafin jiki mai jujjuyawa | Madaidaicin zafin jiki mai jujjuyawa | Curie zafin jiki TC | Matsakaicin zafin aiki TW | Jawabi | |||

| mT | Gs | KA/m | Oe | KJ/m³ | MGOe | 6.9 | % / ℃ | % / ℃ | ℃ | ℃ | |||

| LN10 | ALNICO3 | 600 | 6000 | 40 | 500 | 10 | 1.2 | 7.2 | -0.03 | -0.02 | 810 | 450 | Isotropic

|

| LNG13 | ALNICO2 | 700 | 7000 | 48 | 600 | 12.8 | 1.6 | 7.3 | -0.03 | +0.02 | 810 | 450 | |

| LNGT18 | ALNICO8 | 580 | 5800 | 100 | 1250 | 18 | 2.2 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNG37 | ALNICO5 | 1200 | 12000 | 48 | 600 | 44 | 4.65 | 7.3 | -0.02 | +0.02 | 850 | 525 | anisotropy |

| LNG40 | ALNICO5 | 1250 | 12500 | 48 | 600 | 40 | 5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG44 | ALNICO5 | 1250 | 12500 | 52 | 650 | 37 | 5.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG52 | ALNICO5DG | 1300 | 13000 | 56 | 700 | 52 | 6.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG60 | ALNICO5-7 | 1350 | 13500 | 59 | 740 | 60 | 7.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNGT28 | ALNICO6 | 1000 | 10000 | 57.6 | 720 | 28 | 3.5 | 7.3 | -0.02 | +0.03 | 850 | 525 | |

| LNGT36J | ALNICO8HC | 700 | 7000 | 140 | 1750 | 36 | 4.5 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT38 | ALNICO8 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT40 | ALNICO8 | 820 | 8200 | 110 | 1380 | 40 | 5 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT60 | ALNICO9 | 950 | 9500 | 110 | 1380 | 60 | 7.5 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT72 | ALNICO9 | 1050 | 10500 | 112 | 1400 | 72 | 9 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| Abubuwan da aka bayar na AlNiCo | |

| Siga | AlNiCo |

| Curie zafin jiki (℃) | 760-890 |

| Matsakaicin zafin aiki (℃) | 450-600 |

| Vickers hardness Hv (MPa) | 520-630 |

| Girma (g/cm³) | 6.9-7.3 |

| Resistivity (μΩ · cm) | 47-54 |

| Yawan zafin jiki na Br (%/℃) | 0.025-0.02 |

| Yawan zafin jiki na iHc (%/℃) | 0.01 ~ 0.03 |

| Ƙarfin ɗaure (N/mm) | <100 |

| Ƙarfin karya mai juyawa (N/mm) | 300 |

Aikace-aikace

AlNiCo maganadiso suna da tsayayye aiki da kyau kwarai inganci.Ana amfani da su galibi a cikin mita na ruwa, na'urori masu auna firikwensin, bututun lantarki, bututun igiyar ruwa, radar, sassan tsotsa, clutches da bearings, injina, relays, na'urorin sarrafawa, janareta, jigs, masu karɓa, tarho, na'urar juyawa, lasifika, kayan aikin hannu, kimiyya. da kayayyakin ilimi, da dai sauransu.

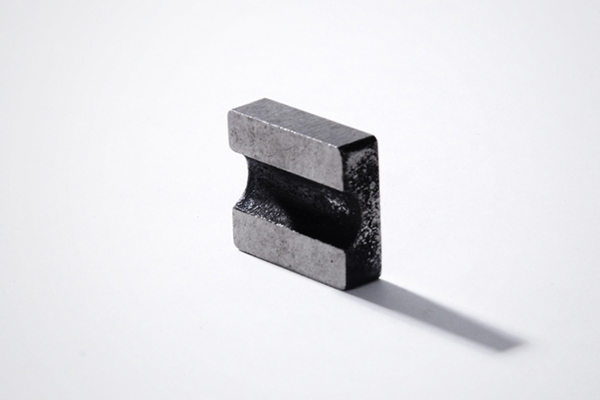

Nunin Hoto